Definition of the storage tank, its types, and the benefits of inspection of the tanks

According to the Environmental Protection Agency estimation, there are over 700,000 bulk above-ground storage tanks spread across the nation.

So, what is the storage tank, and the benefits of inspection of tanks?

Storage tanks are considered a crucial part of modern industries. It is a container that can hold liquids, compressed gasses (gas tank; or in U.S.A “pressure vessel” is not typically labeled or regulated as a storage tank), or mediums used to store heat or cold for a short period of time or over an extended period of time, or for storing petrochemical products and all types of fuel.

Storage tanks are used in many industries such as; petroleum production and refining companies, petrochemical and chemical manufacturing companies, bulk storage and transfer activities, hotels, construction sites, commercial buildings, and so on.

For that, it is considered that Inspections of industrial storage tanks are essential to the smooth and protective operation of any facility. Although the storage tanks and vessels are designed to withstand extreme weather conditions, they can leak if not properly maintained.

These tanks are available in various sizes, with diameters ranging from 2 to 60 meters or more. These are often positioned inside containment basins to prevent spills in the event of tank breaks.

The following are the most prevalent types of storage tanks:

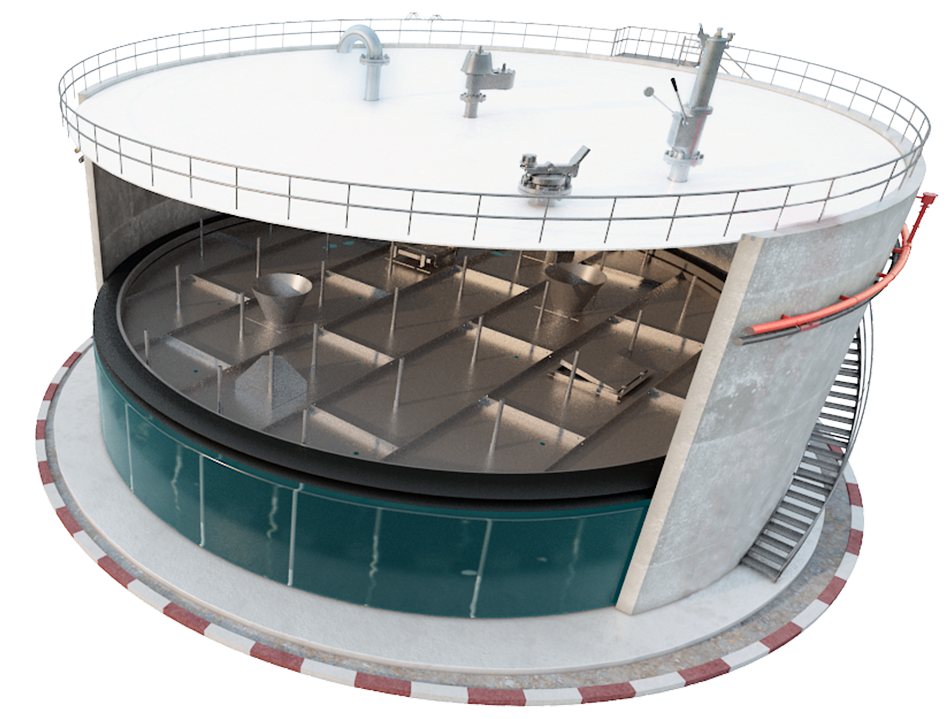

Fixed-roof storage tanks are simple cylindrical storage containers with shallow conical or flat roofs that are welded to the shell. They are frequently used to store large amounts of petroleum distillates, petrochemicals, and other liquid compounds at atmospheric pressure.

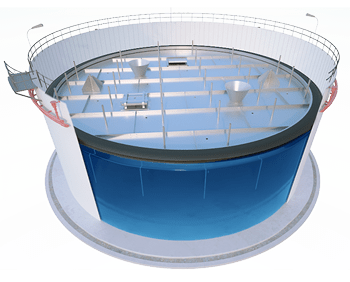

A typical external floating roof storage tank is made of a cylindrical steel shell with an open-top and a roof that floats on top of the liquid being held, rising and falling in lockstep with the liquid level. It is commonly utilized to store large quantities of petroleum products such as crude oil or condensate.

When compared to external floating roof tanks, internal floating roof storage tanks have permanent roofs, which is advantageous for improving the storage conditions of oil products, notably to stop rainwater from getting into the tank and delay the aging of sealing rings.

Domed external floating roof tanks have fixed roofs on top of the shell and strong decks. It is considered the latest in technological evolution.

Horizontal storage tanks are utilized for storing and transporting a wide range of liquid products such as; liquid chemical fertilizers, water, and other liquid agrochemicals such as pest control applications.

Expandable steam tanks are mounted on variable vapor space tanks to handle variations in temperature and barometric pressure.

An LNG storage tank is a specific type of tank that is used to store liquefied natural gas in low pressure. The tank consists from double-walled, with a carbon steel outer wall and a nickel-steel inner tank.

Storage tank inspections

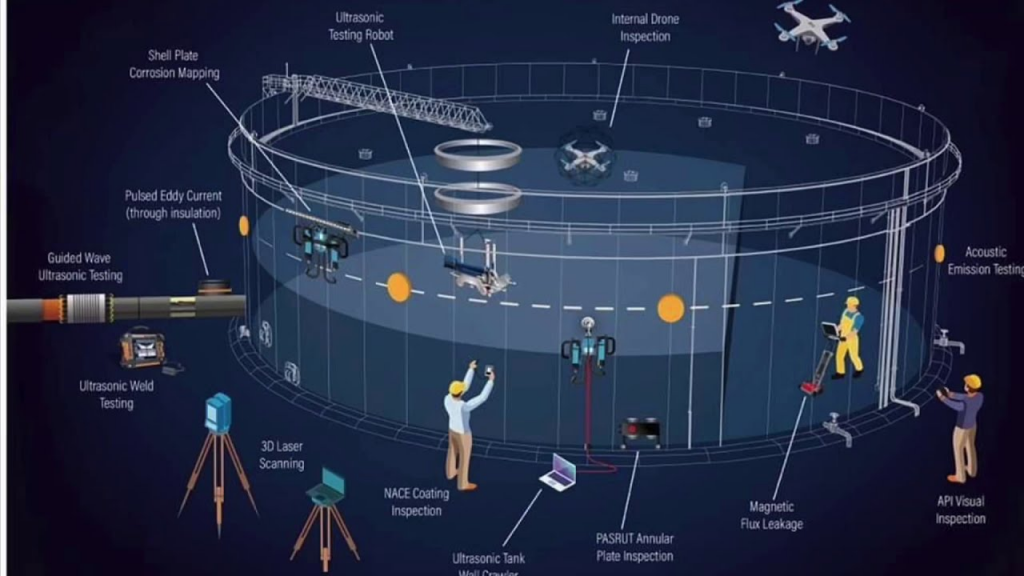

According to the American Petroleum Institute 653 & 650 (API) inspection code and industry standards, all bulk storage tanks should be inspected at least every five years for in-service (on-stream) inspection and every ten years for out-of-service (off-stream).

Numerous serious problems can result from a tank leak. A leaking tank can cause cosmetic issues, expensive repairs, considerable damage, or tank failure. Furthermore, a tank leak can seriously harm the environment and result in accidents at work.

For that reason, regular storage tank inspections are crucial to spotting and resolving potentially disastrous tank problems.

Here are some of incredible benefits of regular industrial storage tank inspection:

Atlas Support & Service Company can do all the necessary inspections of different storage tanks that your business needs to be successful. Which contributes to raising the level of safety of employees and preserving the organization’s property.

Atlas Company offer a wide variety of services during our comprehensive tank inspections such as:

In conclusion, Storage tank inspections are crucial for any company. It reduces maintenance costs, saves your company time and money, and protects workers’ safety. As a result, making inspections for storage tanks are essential, and every company should prioritize it.

Atlas also gives out ISO certificates in a number of areas and does a systematic audit of the work of an organization’s main departments, which is done by an independent party.

If you are looking for our services, or you have some questions, you can contact us via our email (info@atls.com.as) or call on (00966112080550).

And we will be thrilled to assist you.